Best Third Party Manufacturing in Pharma

Saturn Formulations is the leading Third Party Manufacturing in Pharma company that is ISO certified and has more than 20+ various products segment to manufacture while all the manufacturing plants are WHO-GMP certified. Being a leading Third Party Pharma manufacturing company in India we are a one stop solution for manufacturing, leadership, consultancy on Pharma marketing, unique, and innovative packaging to cater the needs of all clients. We make sure all the products are of best quality as rigorous testing and clinical trials are done.

Our company is a leading Pharma third party manufacturing company in India. With the help of our large scale production unit we are able to meet the demand for a variety of drug ranges to our associates. Being one of the best third party manufacturers we have the capacity to deliver all types of drug range such as tablets, capsules, Syrup, Dry Syrup, High Class Injectables, protein powder, and many more. To manufacture the best quality products we use high quality raw material, have the latest machineries, and set up a world class manufacturing unit.

We have a team of professionals and experts who have proficiency with the international industry norms. We have a strong distribution network that helps in delivering products on time to all our valuable customers. We operate within the realm of the top pharmaceutical manufacturers in India.

Saturn formulations are a well-known Third Party Manufacturing in Pharma Company in India that is completely involved in research and development, production, supply, and trading of the solid and liquid form of pharmaceutical formulations such as tablet, capsules, powders, Injectables and oral solutions which requires degree of high-shear granulations, film coating, bi-layers, and more. If you are looking for a contract manufacturing company who are involved in integrated manufacturing can connect with us.

What are the benefits of associating with Third Party Manufacturing Company?

Third Party manufacturing is also known as Contract manufacturing that offers many benefits for businesses looking to outsource their Pharmaceutical production. Here are some benefits of associating with Third Party manufacturer:

- Cost efficiency: Collaborating with leading third party pharmaceutical manufacturers in India or contract manufacturing firms can substantially slash production expenses. These manufacturers have established infrastructure and economies of scale, leading to cost saving for the contracting company.

- Core competencies: Pharmaceutical companies can focus on their core competencies that are research and development, marketing and sales. Also outsourcing the manufacturing process to experts in Pharma third party manufacturing.

- Quality assurance: Reputable pharma companies follow the strict quality standards and regulatory requirements. This makes sure the production of high-quality pharmaceutical products, reducing the risk of product recalls or regulatory issues.

- Scalability: Contract manufacturing allows pharmaceutical companies to improve the production quickly in response to market demand fluctuations. This flexibility helps companies avoid overspending in their own manufacturing facilities.

- Market Penetration: Third Party manufacturing helps in accelerating the product development and launch process. Contract manufacturers generally have well-established processes and can produce pharmaceutical products in lesser time rather than in-house facilities.

- Risk Mitigation: Sharing the production responsibilities with a Third Party medicine manufacturer helps in reducing business risks. If there are any issues with one manufacturing facility, the company relies on others to maintain production.

- Access to expertise: Pharma third party manufacturing possesses specialized knowledge and expertise in pharmaceutical manufacturing processes. This expertise leads to improved product quality and efficacy.

- Regulatory compliance: Reputable contract manufacturing company is well versed in regulatory requirements and helps in ensuring that pharmaceutical products meet all the necessary regulatory standards.

- Cost consistency: It generally involves clear pricing, hence making it easier for pharmaceutical companies to predict and manage production costs.

- Infrastructure savings: By getting access to existing infrastructure of Third Party manufacturing Pharma Company, pharmaceutical companies can avoid the investments in building and maintaining their own manufacturing facilities.

- Customization as per requirement: Contract manufacturers generally offer customization options to meet the specific needs and requirements of pharmaceutical companies and allows a tailored approach to production.

Third Party manufacturing provides pharmaceutical companies with many benefits such as cost reductions, quality assurance, scalability, and access to specialized expertise. This approach helps companies to optimize their operations, reducing risks, and to penetrate the market with enhanced efficiency.

Product Range offered in Third Party Manufacturing by Saturn formulations

Saturn Formulations as the Top leading Third Party Manufacturer in India gives the best quality and a wide range of product range such as:

- Tablets | Capsules

- Soft Gel Capsule

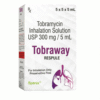

- Injectable

- I.V. Fluids

- Syrup | Dry Syrup

- Eye | Ear Drops

- Nasal Spray

- Ointment | Gel

- Protein Powders

- Creams

- Lotion

- Face Wash

- Shampoo | Soap

What are the documents required for taking Third Party Manufacturing?

To engage in Third Party Manufacturing in Pharma companies generally need to provide essential documents such as:

- Drug License

- GST Certificate

- Quality control documents

- Manufacturing agreement

- Product Designing and composition

All these documents help ensure compliance with regulatory standards and establish clear terms for the manufacturing partnership.

What is the process of Third Party Pharma Manufacturing?

Client Engagement: The process begins with the Client Company that may be a pharmaceutical brand or company, approaching a third party manufacturer for their manufacturing needs. The client shares the product requirement, including formulation, quantity, quality standards and timelines.

Product Formulations and Specification: The client provides the contract manufacturer with formulation details including the APIs (Active Pharmaceutical ingredients), excipients, as well as specific product requirement and quality standards.

Regulatory Compliance: The contract manufacturer ensures that facilities and processes comply with the regulatory requirements of the region where the pharmaceutical products will be sold. Typically, this entails acquiring the necessary licenses and approvals.

Raw Material Procurement: The manufacturing companies source the required raw material that includes APIs from the approved supplier. These materials are tested for quality and compliance.

Production: The manufacturing process involves blending, tablet, granulation, encapsulation, or other processes depending on the type of pharmaceutical product. Strict quality control measures are implemented throughout production.

Quality assurance: Various tests and inspections are done by a team of experts to ensure that the pharmaceutical products meet all quality and safety standards. This includes testing for purity, efficacy, potency, dissolution and stability.

Packaging: Once the pharmaceutical products pass quality checks and are packed according to the client’s specifications. Proper packaging and labelling are critical for compliance with regulatory requirements.

Documentation: All manufacturing and quality control processes are carefully documented to maintain a comprehensive record of production activities. This documentation is important for regulatory compliance and traceability.

Delivery: The finished products are then delivered to the client company’s distribution center or designated location according to the agreed upon terms.

Regulatory Filing: In some cases the contract manufacturer might assist the clients in preparing and submitting regulatory filings such as new medicines applications, depending on the authority and the nature of the product.

Conclusion:

Third Party Manufacturing is a cost effective and time saving business model which allows companies to focus on their core competencies area while ensuring the best quality products at affordable price and on time. Saturn formulations is a leading Third Party Pharma Manufacturing company in India which provides high quality services to pharmaceutical companies. The company’s state of the art manufacturing facility and specialized team ensures that the products meet the highest quality standards. If you are looking for the best pharma product manufacturing company, Saturn Formulations is the best, reliable and trustworthy partner.

Frequently Asked Questions:

What is Third Party Manufacturing?

Third Party manufacturing involves a business arrangement in which a pharmaceutical company assigns the production of its products to an external third party manufacturer. This third-party manufacturer takes on the responsibility for the entire manufacturing process, including quality control and frequency.

What advantages does Third Party Pharma Manufacturing offer?

Third Party manufacturing pharma offers benefits such as cost savings, specialized expertise, and increased production capacity and the flexibility in production without the need for capital investments.

What is Pharmaceutical Contract Manufacturing?

Contract manufacturing is alternatively referred to as third party manufacturing. It entails subcontracting the production of pharmaceutical products to a specialized manufacturing company.

How do Third Party manufacturing companies ensure quality and safety?

Companies ensure product quality and safety by following strict regulatory compliance and conducting rigorous quality control tests. Also maintain good Manufacturing practices (GMP) compliance.

How can pharmaceutical companies benefit themselves from Third Party Manufacturing products?

Pharmaceutical companies can benefit from third party manufacturing products by reducing the production costs, focusing on research and marketing. Expanding the product offering without the need for extensive in-house manufacturing facilities.

What is the process involved in Third Party Manufacturing?

The procedure includes choosing an appropriate manufacturing collaborator, communicating product specifications, performing quality assessments, producing the items, ensuring quality, packaging, and distributing them.

Why do Pharmaceutical companies opt for Pharma contract manufacturing?

Companies choose Third Party pharma manufacturing to reduce the production costs, reduce risks and leverage the expertise of specialized manufacturers.